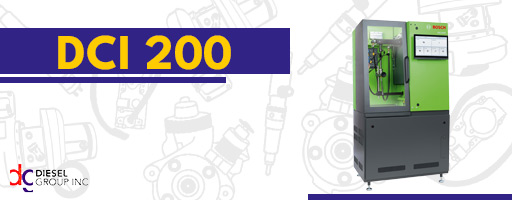

DCI 200 – single common-rail Injector test bench

The Bosch DCI 200 diesel test bench is designed with the future in mind with its measurement system that has the ability to code and test passenger car and commercial vehicle common-rail injectors with the latest injection technologies such as Needle Closing Control (NCC) and Valve Closing Control (VCC) for EURO 5 as well as EURO 6 injectors.

Thanks to the short mounting and testing time, the DCI 200 offers you and your workshop outstanding test efficiency. A standard injector can be tested in less than 15 minutes.

Designed with a tapered base, it allows the operator to stand closer to the test bench during mounting without diffraction. This is one of the many ergonomic features that make the DCI 200 so easy-to-use.

SKU:

0 683 225 001

Categories: Bosch Test Equipment, DCI 200

Description

More Information

Features and Benefits

- Saving time through the fast setup and a testing time of 15 minutes

- High effectiveness through patented rotating rail concept – no vulnerable high pressure hoses required, lower maintenance cost and easier setup

- Higher quality, reliability and transparency for Bosch injectors thanks to fast and precise testing – including IMA/NIMA coding

- Capable of testing common-rail injectors with state-of-the-art VCC (Valve Closing Control) and NCC (Needle Closing Control) technologies for EURO 5 and EURO 6

- Elimination of the use of additional accessories thanks to automatic setting of the return back pressure

- Always current through regular online updates

- Ergonomic design with the slanted lower part, allowing closer standing proximity and therefore improved working comfort at the test bench

- Modular retrofit kits for commercial vehicles and off-highway common-rail injectors – from Bosch and other manufacturers

Technical Data

| Model | DCI 200 |

Test pressure | 25 MPa ... 270 MPa |

Mechanical pressure limitation | 285 MPa |

Rail pressure control | with 2 pressure control valves (PCV) and metering unit in CP4.1 |

Automatic injector back pressure control | 50 kPa ... 1200 kPa |

Used HP pump for test pressure generation | CP4.1 (CP4-25) |

Capacity of test oil tank: at the max. marking at the min. marking | 15 l 12 l |

Tightening torques of high-pressure connections, locking screws | 20 ... 25 Nm |

Dimensions w/o swiveling arm (W/H/D in mm) | 910 × 1,736 x 786 |

Dimensions with swiveling arm for monitor and keyboard tray (W/H/D in mm) | 1,010 × 1,736 × 900 |

Weight w/o test oil | 415 kg |

Operating System | Windows 10 IoT, 64 Bit |

| AC Voltage supply | 230 +/- 10 % VAC (0 683 225 001) with PC and display |

Rated current | 15 A |

Fuse | 16 A |

Phases | 1P - PE |

Input frequency | 50 / 60 Hz |

Protection class entire test bench | IP 20 |

Air pressure, corresponds to a height of | 700 hPa – 1,060 hPa ≤ 2.200m |

Workplace-related emission sound pressure level according to DIN EN ISO 11201 | < 69,2 dB(A) +/-2,5 dB |

Operating temperature | 5 °C ... 40 °C |

Max. permissible relative humidity | ≤ 90 % (at 25 °C and 24 hours duration) |

Storage temperature | -20 °C ... 60 °C |

Software and database updates | via DDM (Diagnostics download manager, internet connection prerequisite) |

Scope of Delivery

- Injector test bench DCI 200

- High pressure pump CP4.1 with metering unit

- Swiveling rail concept with 2 PCV (pressure control valve) and PLV (pressure limiting valve)

- CRI accessory kit for solenoid and piezo common-rail injectors

- Electric CRI connection lead (2, 3, 4 pin)

- 15,6'' LCD Touchscreen display

- Working area lightning for leak test evaluation

- Operating instruction

Special Accessories

CRIN 1, CRIN 2, CRIN 3 | 1 687 010 207 |

CRIN 4.2 | 1 687 010 209 |

CRIN 3rd Party | 1 687 010 208 |

Swiveling arm for monitor and tray for keyboard and mouse | 1 687 016 221 |

Insert shelf | 1 685 200 650 |

Holding device for BQS scanner | 1 685 200 178 |

Adapters for CRIN injectors |

Downloads

Segment Brochure (PDF) | |

DCI 200 Brochure (PDF) | |

Manuals, updates and information |